Porsche Press kit 1975 - landing page

IAA '75 Thyssen-major supplier to the automobile industry steel plays an important role in the materials used in automobile construction. A car, for example, is more than 2/3 of its weight made of steel. The automotive industry will find a capable partner in the Thyssen Group who has fully adapted to the technological demands of the automotive industry. The individual companies in the group supply the appropriate materials for almost all manufacturing processes in which steel parts for automotive engineering are made - from stainless steel and body sheet metal to spring steel wire. Welding consumables and specially designed connecting elements also contribute to efficient automobile production. At the joint stand in Hall 5 a, the range of services offered by the group and the various areas of application of steel in automobile construction will be demonstrated to visitors through exhibits, slide shows and films. The car show is intended to inform the public that the close cooperation between the automotive industry and Thyssen is contributing to the development of products that are important for greater safety and longer vehicle life. August Thyssen-Hütte, an important manufacturer of sheet metal, increasingly supplies galvanized and aluminized sheet metal to the automotive industry.

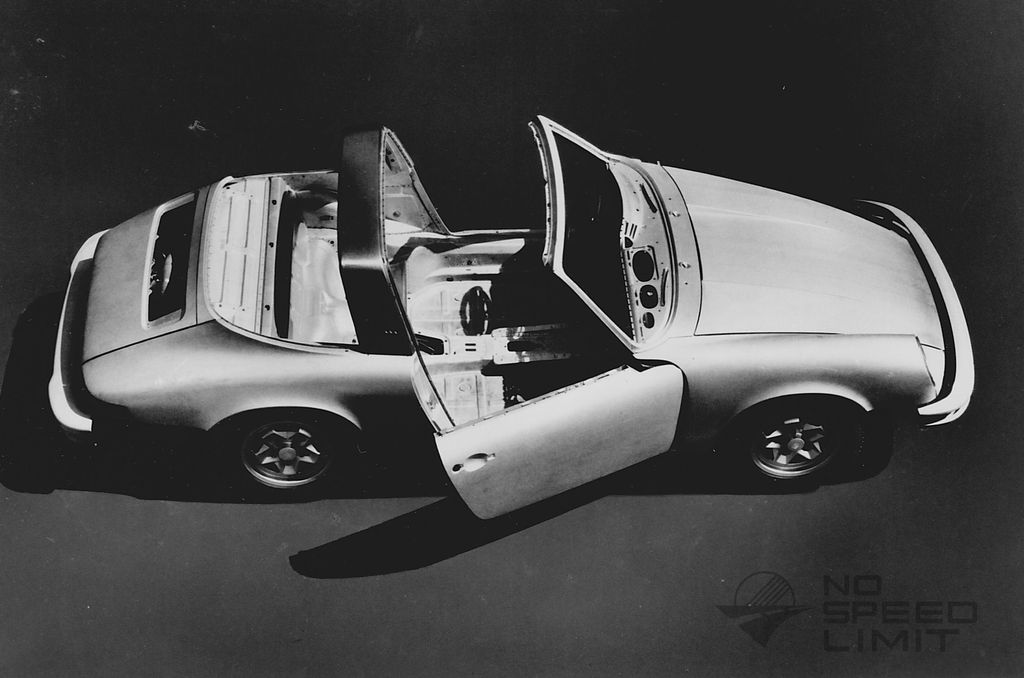

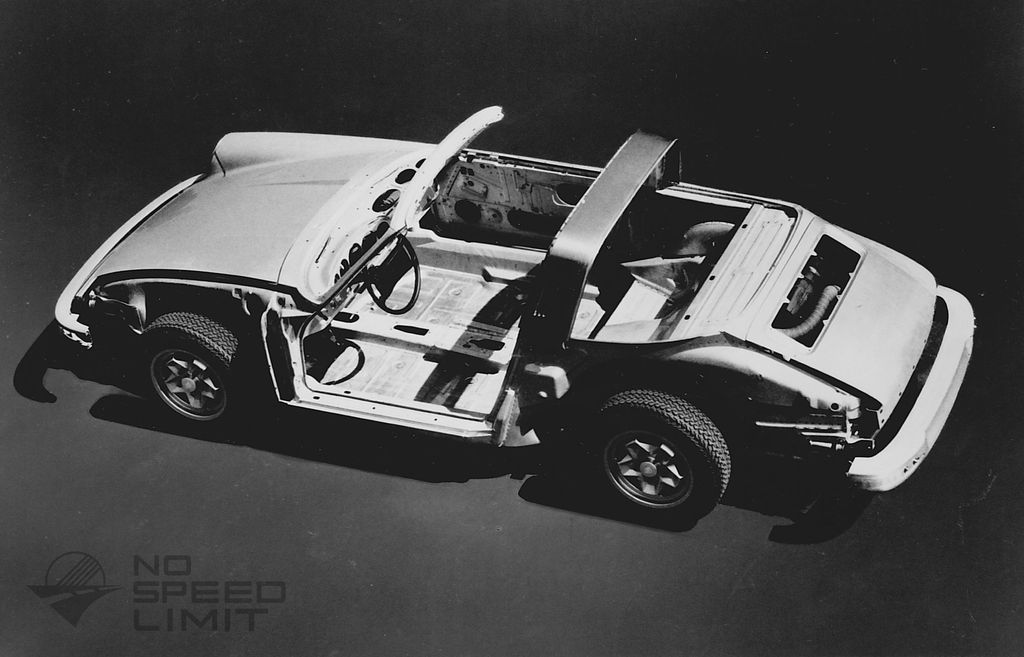

These materials, which are used in particular for components at risk of corrosion, largely protect against rust. The Porsche company in Stuttgart-Zuffenhausen, for example, uses hot-dip galvanized Thyssen steel sheet for the 76 series models as a corrosion-proof material for the entire floor pan and in the manufacture of the body parts. In the body shop, hollow bodies at risk of condensation can also be used for the hot-dip galvanized material, i.e. cross members and side members, door sills, but also cover and web plates, air conditioning systems, spare wheel bins, etc. However, especially for body parts that are particularly vulnerable to falling rocks are at risk (fenders, wheel arches, front sheet metal, headlight trim). This is one of the main advantages of hot-dip galvanized sheet metal: the cathodic protective effect of the zinc layer in the event of mechanical damage, which prevents corrosion of the steel sheet underneath for a long period of time. Due to the very good adhesion of the zinc coating, rusting underneath a damaged area is largely avoided. Thyssen Niederrhein belongs to the leading international group of wire rod producers. Enka Glanzstoff, one of the leading manufacturers of steel cord for radial tires, uses rolled wire from Thyssen Niederrhein in a special quality intended for this purpose as the raw material.

Thyssen Edelstahlwerke will be demonstrating at the IAA '75 the advantages of engineering steels for moving automobile parts or of stainless steels for areas particularly at risk of corrosion. After years of intensive development work, a ferro-titanite quality was created for the sealing strips in rotary piston engines, which significantly increases the service life of the rotary engine. Rheinstahl Umformtechnik und Bergbautechnik as well as Bergische Stahlindustrie show their range of services for the automotive industry on separate exhibition stands in Hall 4

Porsche Press kit 1975 - landing page

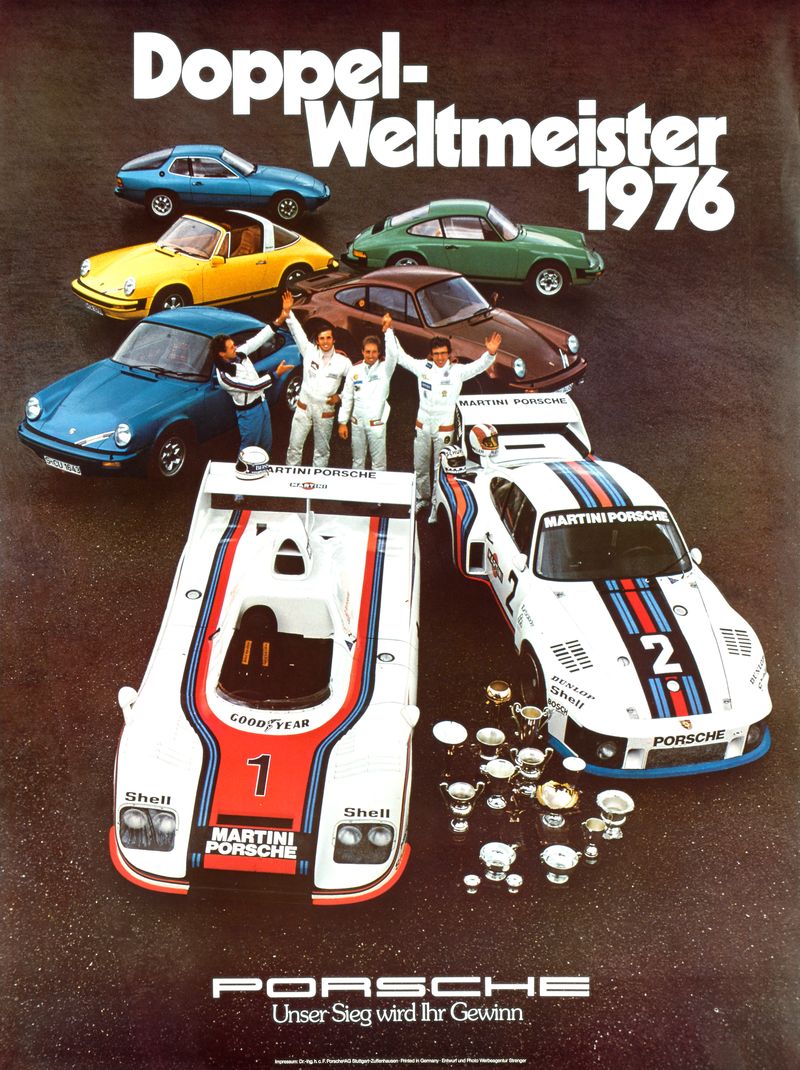

Porsche Press kit 1976 - landing page

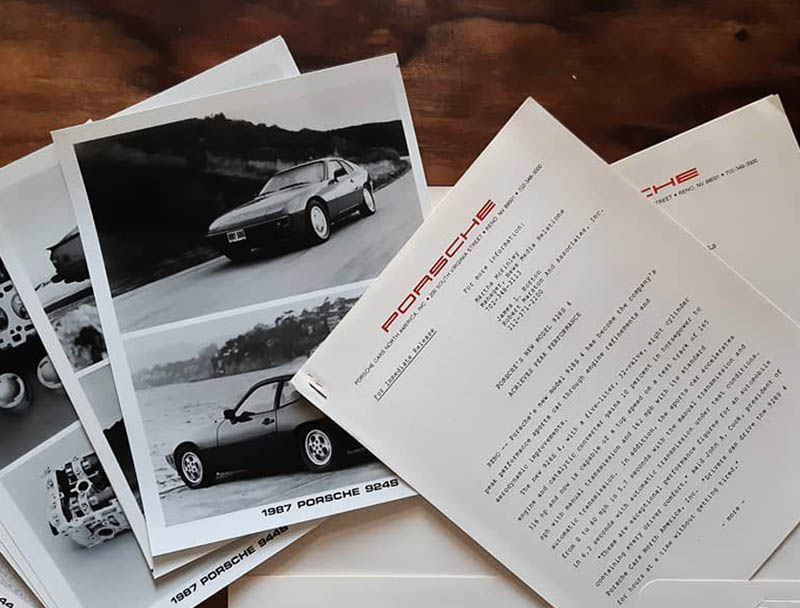

Porsche Press kit

Porsche Literature

Our Porsche Cars