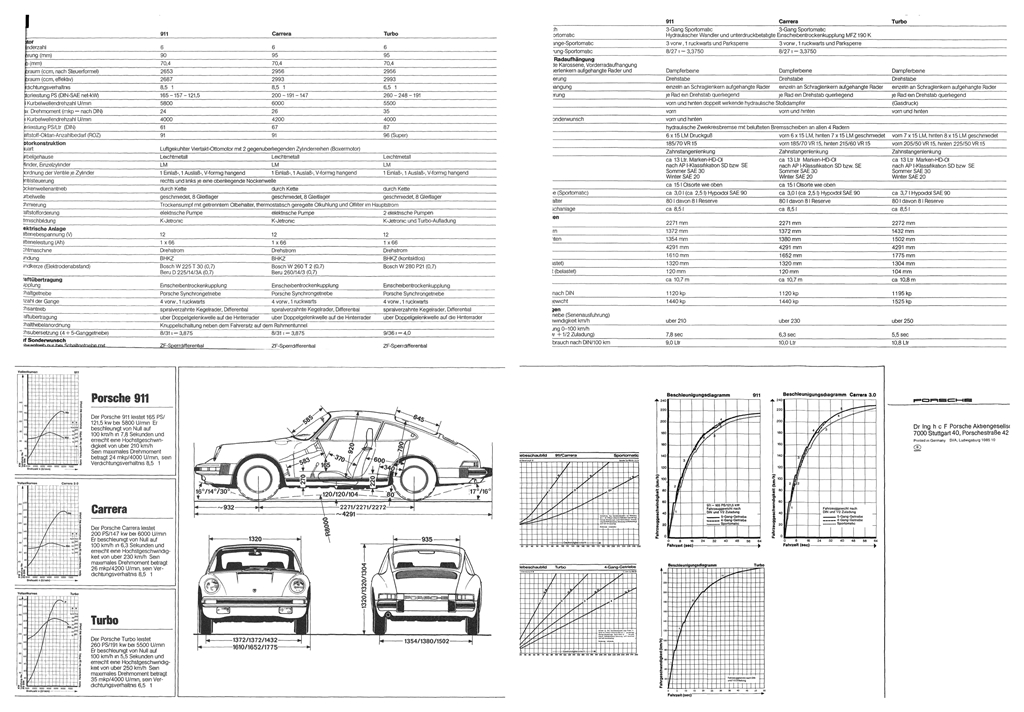

1975 Tech Data

With the "three-model range" of 911, Carrera, and Turbo, the Zuffenhausen-based sports car manufacturer has returned to a long-standing tradition. Also traditional is their long-standing commitment to designing the sports car "sensibly," despite or perhaps even because of its exclusivity. Sensibly, that means:

All these aspects were refined for the 1976 Porsche models with the renowned Swabian attention to detail. The result:

The customer-friendliness of all these measures culminates in the new factory warranty periods: Porsche vehicles have a new full-year warranty from model year 1976 onwards – without any restrictions based on mileage.

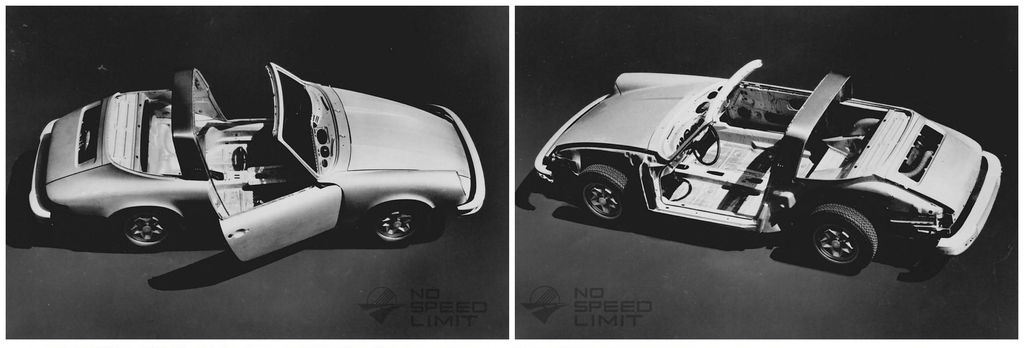

Furthermore, Porsche can afford to offer an additional six-year warranty against corrosion on the entire body-on-frame. This is because the bodies of the Zuffenhausen sports cars are now—and this is a first in automotive production—made from hot-dip galvanized Thyssen steel sheets. This brings Porsche cars significantly closer to the ideal of the rust-free vehicle.

With the 1976 model year, Porsche took a decisive step towards a more durable car. Through the extensive use of galvanized sheet metal and rust-resistant components, Porsche cars set new standards for longevity. A 6-year warranty on load-bearing body parts and a 1-year warranty with unlimited mileage for the entire car are the customer-friendly result of these measures.

The progressive and innovation-driven Porsche company is renowned for pioneering achievements in both the distant and more recent past. The early conversion of Porsche engines to run on regular gasoline in 1972 and the presentation of the Long-Term Car research project at the 1973 IAA (Frankfurt Motor Show) are recent examples. Both aimed at improved environmental friendliness, but also at increased efficiency, which rising costs of driving and dwindling raw material reserves for car manufacturing increasingly demanded. The conversion of the Porsche 911 series to more durable components aims in the same direction, resulting in a longer lifespan, increased service life, and greater resale value.

Starting with the 1976 model year, Porsche has used hot-dip galvanized body panels for the 911 models. The Thyssen steel panels, coated on both sides, guarantee years of protection against corrosion precisely where it typically occurs and where TÜV inspections are required.

Porsche opted for hot-dip galvanizing only after extensive testing of various zinc coating methods. Ultimately, several advantages tipped the scales in favor of hot-dip galvanizing: The zinc coating applied to both sides of the panels is thicker. It measures at least 10M, 20M on particularly vulnerable parts such as the door sills or the front axle mount, and 50M on the rear axle tube. In addition, there is an intermediate layer that forms only at the high temperatures of hot-dip galvanizing (the sheets are red-hot during this process), created by an intermetallic iron/zinc compound. Furthermore, if the protective coating is damaged, galvanized sheets develop cathodic protection; triggered by an electrochemical series (zinc anode, iron cathode), the zinc is able to migrate across distances of up to several millimeters on its own. Damage to the protective coating on the inside is virtually nonexistent. Protection against the more dangerous internal corrosion is therefore largely perfect.

But what happens in the event of repairs if cutting or welding work has damaged the protective coating? This was also considered and addressed during the course of the test series. Result: By applying a suitable primer (e.g., zinc dust paint), corrosion protection can be largely restored and maintained.

And what about the disadvantages of using hot-dip galvanized sheet metal? Primarily, there is the price of the sheet metal, as well as its more difficult and complex processing. This means that a hot-dip galvanized body is more feasible for a small series of high-quality automobiles like those from Porsche than for mass-produced average cars. A steel sheet metal body (including outer skin) as extensively galvanized as the one now being manufactured by Porsche is a novelty in automotive engineering.

The introduction of galvanized sheet metal is the latest measure by Porsche in a comprehensive program to increase the lifespan of its components.

The longevity and cost-effectiveness of the Zuffenhausen sports cars exceed the norm. The long-term preventative measures already in place, such as permanent cavity sealing (i.e., requiring no further treatment), underbody protection, and the high-quality paint finish of Porsche cars with electrophoretic primer, remain fully intact. The early and comprehensive approach Porsche took to longevity is particularly evident in the gradual introduction of rust-free components in the 911. Since 1973, the sports cars from Zuffenhausen have featured a completely rust-free, and therefore unpainted, stainless steel exhaust system. The leaded fuel tank (with a PVC coating on the outside) and the oil tank of the dry-sump lubrication system, which supports the engine's longevity, are also rust-free.

These are also rust-free. Furthermore, the proportion of rust-free aluminum components in Porsche vehicles is constantly increasing, including:

These aluminum parts contribute to both the longevity and the low, economical overall weight of the sports cars. The stainless steel Targa bar is another example of a corrosion-free Porsche component.

Hand in hand with the increased lifespan and mileage of Porsche cars goes a reduction in maintenance requirements.

The use of permanently lubricated or frictionless bearings and joints in the chassis, and the low oil contamination thanks to dry-sump lubrication (11 liters of oil capacity), made it possible as early as 1973 to extend service intervals to 20,000 km.

New additions to this puzzle are the contactless and therefore maintenance-free ignition of the Porsche Turbo, as well as the long-life 50 percent tires available for the Carrera and Turbo models.

Economic efficiency, one of the current imperatives of this automotive age, requires two things: a functional concept and above-average manufacturing effort. Both of these prerequisites are met by Porsche and have been consistently utilized. Following the demands of the times, the sports car's low weight, excellent aerodynamics, and small frontal cross-section, combined with a precisely functioning fuel-air mixture preparation system, resulted in exceptionally low fuel consumption. The sophisticated engineering of Porsche cars translated into longevity, low maintenance, and lasting value.

This adaptation process—and this is crucial for Porsche—did not come at the expense of classic Porsche qualities. Even with the 1976 models, Porsche offers superior performance, above-average driving safety, sophisticated exclusivity, and the joy of active driving, but also a Porsche that sets new standards through its durability, efficiency, and value retention.

With the long-lasting 911, Porsche once again demonstrates the pioneering role that the sports car plays, and will continue to play, in automotive development due to its functionality and sophisticated technology.

August 1975

Dr.Ing.h.c.F.Porsche

Aktiengesellschaft

Presseabteilung

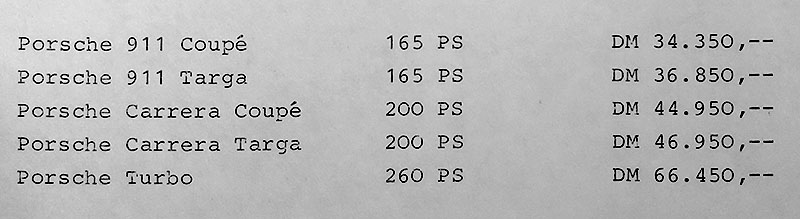

Compared to the recommended retail prices of the 1975 Porsche models, the prices have hardly changed.

However, if you consider the more extensive standard equipment, such as automatic climate control in the Porsche Carrera 3.0 (previously DM 690 extra) and the now included 50% tire discount in the base price for the Turbo (previously DM 800 extra), the Porsche Carrera and Porsche Turbo models cost less than their predecessors. The new Porsche 911, in terms of equipment, performance, and price, sits precisely between its predecessors, the 911 and 911 S. The recommended retail prices are:

1975 Tech Data

1977 production

Porsche Press kit

Porsche Literature

Our Porsche Cars