Porsche 911 - Engine Development

The water-cooled six-cylinder of the Boxster and the new 911 set the standard for contemporary sports engines.

"Our loyalty to the six-cylinder boxer engine is more than tradition", explains Horst Marchart, Chief Technology Officer at Porsche and head of the Weissach Research and Development Center.

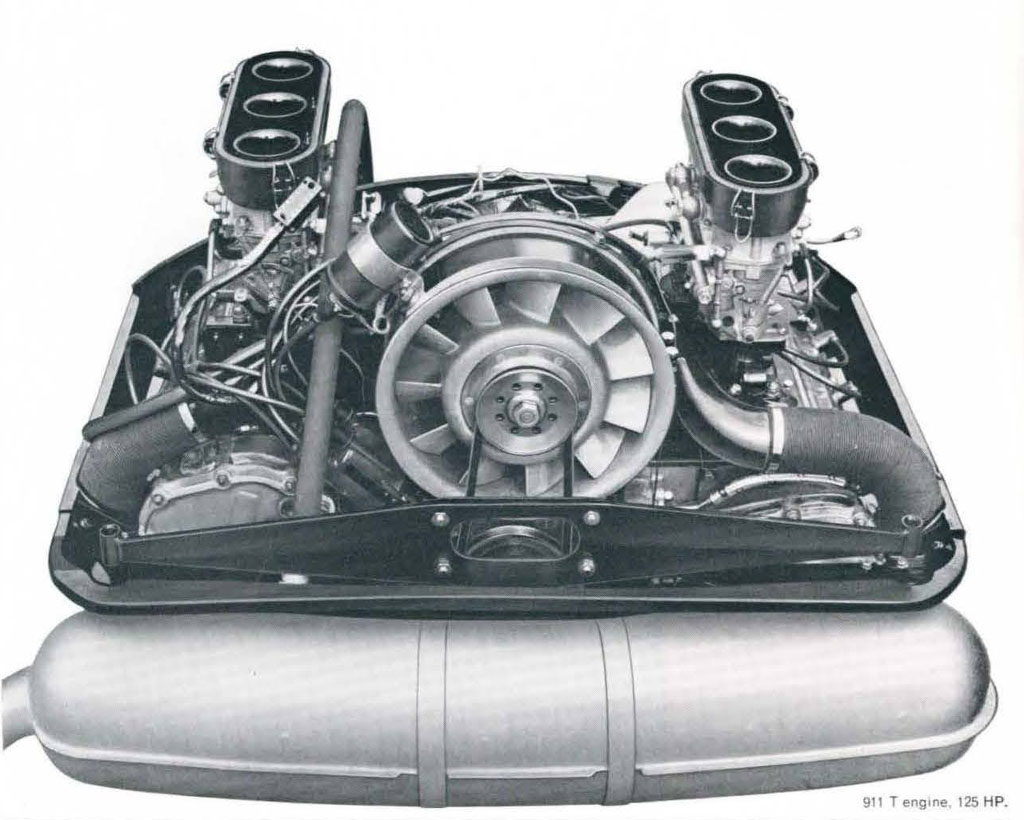

With its flat design, the boxer engine is an ideal match for the two Porsche concepts: the central engine of the Boxster and the rear engine of the 911. The counter-rotating operation of its pistons ensures perfect smooth running. In a six-cylinder boxer there are neither free mass forces nor free mass moments. Here the crank drive works perfectly balanced. This is not only expressed in mechanical good behavior, it also allows a sports engine to advance stress-free into high speed regions.

The change from air to water cooling was a technically necessary step in order to safely master the four-valve technology. Four valves per cylinder are indispensable today if you want to achieve high performance, low consumption and low levels of pollutants in the exhaust gas.

At Porsche, the clear commitment to water cooling is based on many years of practical experience. And this is not only based on the good properties of the water-cooled series engines with four and eight cylinders. The TAG engine, with which McLaren became Formula 1 world champion three times, was a water-cooled V6, designed by Porsche ". Porsche has been building water-cooled six-cylinder boxer engines for GT racing cars since 1977 Motor sport started, which continues to this day, because engines of this type are in the racing car of the 16-time Le Mans winner Porsche, including the very young hero 911 GT1 98, who finished the Le Mans 24-hour race in June with a double victory.

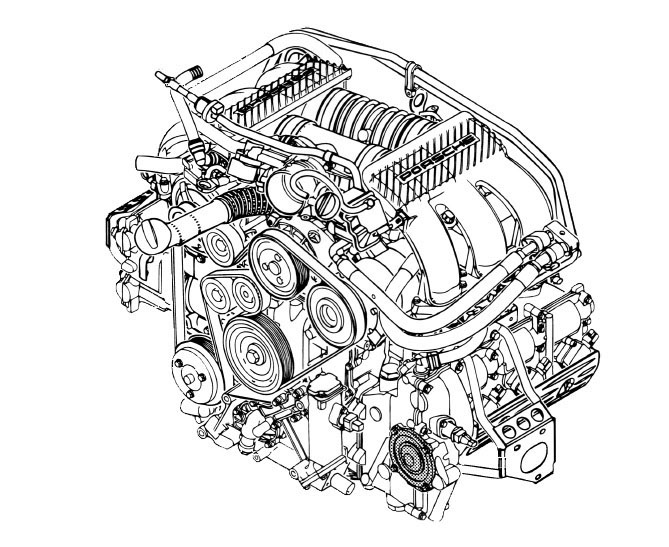

The construction of the Carrera engine differs from these racing machines. In their basic structure, the engines of the Boxster and Carrera are the same. In terms of displacement and power, however, the two six-cylinder units are clearly at a distance. 25 liters and 204 PS (150 kW) are the measure of all things for the Boxster, the 911 Carrera with 3.4 liters and 300 PS (221 kW) really adds up.

Architecture and materials identify the new Porsche boxer engines as ultra-modern engines designed far into the future. The two-part crankcase, separated in the middle, is made of light metal die-cast. This material with its good surface quality allows perfect production of very filigree shapes and therefore also very light housing parts. This die casting is only unsuitable for the cylinders and their highly stressed raceways. That is why when casting the housing, the six cylinder liners made of a silicon alloy are placed in the mold and cast.

Another specialty of the Porsche engine is the separate bearing bracket in which the crankshaft with its seven main bearings and an intermediate shaft run. The aluminum block, which encloses the central part of the crank drive, contains support elements made of cast steel, which allow the bearings a tight fit. In the Carrera engine, which has a maximum speed of 7,300 revolutions per minute, this component is reinforced inside far more powerfully than in the Boxster machine, whose rev limiter kicks in at 6,700 revs.

The design of both engines is sporty with a large bore and short stroke, which is useful for both smoothness and speed stability. The dimensions for bore and stroke are 85.5 millimeters and 72 millimeters for the Boxster and 96 millimeters and 78 millimeters for the 911.

These Carrera boxer engines show a departure from the traditional Porsche design when it comes to the oil circuit. The classic dry sump lubrication of the 911 engine required a separate oil tank to store around twelve liters, which was connected to the engine via lines. The integrated dry sump lubrication system now hoards its oil reserves of around 10 liters in a chamber in the engine housing, which is separated from the working area of the crankshaft.

The next example of technical progress is the boxer in its cylinder heads. Two camshafts rotate in each of the two, actuating two intake and two exhaust valves per cylinder. Doubling the number of valves has three main advantages:

With the four camshaft drive, Porsche is adding another remarkable example to the diversity of engine construction. The power flows from the crankshaft via a chain to the intermediate shaft already mentioned. This drives two more chains to the exhaust camshafts with one pinion each on its front and rear ends. This offset solution saves space because it uses the offset of the cylinder rows on the left and right to accommodate the two chain shafts. Not least because of this design, the water-cooled boxer is 70 millimeters shorter than the air-cooled version of its predecessor with the same cylinder spacing

By using two camshafts and a camshaft adjuster, the current six-cylinder can vary the timing of the intake valves by 25 degrees. This is done by a hydraulic camshaft adjuster on the chain between the exhaust and intake camshafts. The intervention in the control of the machine has several positive consequences:

If Porsche technicians replace air cooling with water cooling, then it inevitably has to be special water cooling. To "refresh" the cylinders and combustion chambers of the Boxster and 911, they chose a principle that is otherwise common in racing engines. The cooling water flows are clearly separated on each side - by the cylinder head gasket The cylinder heads and the cylinder rows are not flowed through longitudinally, as is usually the case with series engines, but - to the taste of racing technicians - transversely in front of the exhaust to the intake side. The return occurs via two separate longitudinal ducts. The advantage of this system is that cylinder heads and cylinders are evenly supplied with coolant as required.

The water cooling ensures a balanced heat balance in other areas as well. The coolant flows through a heat exchanger with the engine oil. The water, which has risen quickly to its operating temperature, warms up briefly here.. However, if the oil becomes warmer than the water during a brisk drive, the temperature is equalized in the opposite direction: the oil is cooled by the water. The automatic oil is cooled in the same way if a Tiptronic is available. In this case, by the way, the 911 has three water coolers in the bow.

The intake system, which is mainly made of light fiber-reinforced plastic, has a large share of the high performance and the hefty torque of the two boxer engines thanks to its aerodynamic shape, its correctly coordinated pipe lengths and the smooth surfaces of the ducts. The six intake pipes that lead to the intake valves open into an air collector on the opposite side in a pack of three. The engine of the 911 has another special feature: the flap is opened up to 2,720 rpm, above this it is closed up to a speed of 5,160 rpm and then opened again in the upper area. This solution makes it possible to achieve the highest cylinder charge and the best torque or the highest power in each of the three areas.

On the other hand, the exhaust gas expects an exhaust system made of stainless steel with two metal catalysts, which ensure thorough exhaust gas cleaning.

The lively traffic of sparks - when there are 6,000 crankshaft revolutions per minute, 300 sparks flash per second in the six-cylinder - is controlled by a computer. Thanks to the anti-knock control, the computer also finds a suitable ignition point for less good fuel quality than Super Plus. And as usual, the injection system works with electronic management, which sends 300 or more correctly measured portions per second at the right time in front of the inlet valves if required.

The large array of innovations for the water-cooled boxer engine results in the Porsche 911 with a high output of 300 hp (221 kW) at 6,800 tours. The maximum torque of 350 Newton meters is 4,600 revolutions. But the progress that these numbers describe lags far behind the real driving experience.

The water boxer in the 911 reveals the true brilliance of its technology when high speeds are required. Then, with enormous thrust, it develops an apparently uninhibited turning ability up to the seven-thousand-meter region.

The sound that accompanies this new fortissimo of turning is law-abiding, but the key is still unchanged: Porsche, six-cylinder boxer.

Porsche 911 - Engine Development

.jpg)

Porsche Formula 1 engine TAG Turbo PO1

Porsche Press kit

Porsche Literature

Our Porsche Cars