Porsche Press kit 2000

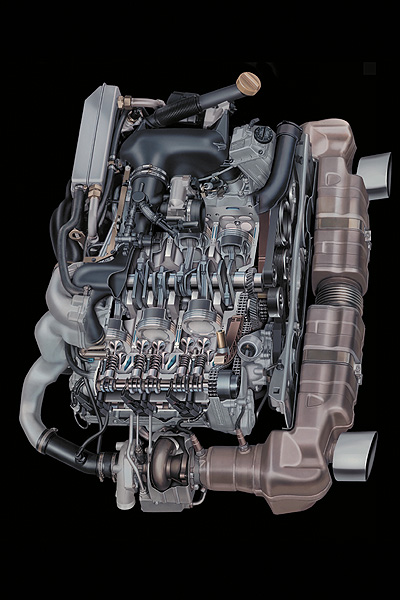

The all-new fourth-generation Porsche® 911™ Turbo makes a drastic departure in engine philosophy from its predecessors. Previous models used turbocharged versions of air-cooled Carrera engines in 3.0, 3.3, and 3.6-liter form. However, the engine in the 2001 911 Turbo is not a turbocharged version of the engine from the current 911 Carrera models. Instead, Porsche derived the 3.6-liter, horizontally opposed six-cylinder engine in the 2001 911 Turbo from the Porsche GT1 racecar, which won the 24 Hours of Le Mans in 1998.

Liquid cooling, used for the first time in a 911 Turbo, allowed significant increases in both compression ratio and turbo boost pressure. The new 911 Turbo engine uses a 9.4-to-1 compression ratio, compared to 8.0-to-1 for the previous air-cooled 911 Turbo. (The first 911 Turbo, by further comparison, used a 6.5-to-1 compression ratio!)

The 911 Turbo engine produces 415 horsepower (309 kW) @ 6,000 rpm and sustains 415 lb.-ft. (560 Nm) of peak torque from 2,700 rpm to 4,600 rpm. Power drives through a standard six-speed manual transmission. For the first time in a 911 Turbo, Porsche offers the advanced Tiptronic S five-speed automatic transmission as an option.

With power characteristics of a far larger engine, the 2001 911 Turbo (six-speed) can accelerate from 0-62 mph (0-100 km/h) in just 4.2 seconds. On the test track, the 911 Turbo will sprint from a standstill to 100 mph (160 km/h) in only 9.2 seconds and can achieve a top track speed of 189 mph (305 km/h).

When equipped with the optional five-speed Tiptronic S automatic transmission, the 2001 911 Turbo offers still-staggering performance: 0-62 mph (0-100 km/h) in 4.9 seconds; 0-100 mph (0-160 km/h) in 10.6 seconds and a top track speed of 185 mph (298 km/h).

The 911 Turbo engine shares the GT1’s pressure-cast light-alloy split crankcase, and the crankshaft runs through eight bearings. The stroke measures 3.01 in (76.4 mm) and the cylinder bore measures 3.94 in. (100.0 mm) for a displacement of 3,600 cc (220 cu. in.). Each side of the crankcase (cylinder block) includes a separate cylinder head and camshaft housing, both of which bolt to each crankcase side. In contrast, in the 911 Carrera engine, the cylinder and crankcase sections form one unit. The modular construction reveals the engine’s racing heritage – it facilitates displacement changes to comply with ever-changing racing regulations.

The 911 Turbo does use the same kind of racing-derived crossflow cooling as the 911 Carrera 4 engine. Coolant flows crosswise from the hot to the cold side of the engine, ensuring a consistent temperature curve. The coolant system includes an oil cooler. During engine warm-up, the engine coolant helps heat the oil to bring the engine up to operating temperature quickly.

The front of the 911 Turbo, with its three large intakes, shows off the cooling capacity required by the twin-turbo engine. The central intake feeds a third radiator, which increases the cooling capacity by 50 percent over the two-radiator 911 Carrera 4. The water pump can flow 4,500 gallons per hour – about 800 more than the 911 Carrera 4.

As on the previous-generation 911 Turbo, the 2001 model uses dual turbochargers, arranged in parallel. Also like the previous 911 Turbo, the 2001 model uses dual intercoolers, but they’re mounted on each side behind the rear wheels instead of on top of the engine.

Intake air enters through an inlet in the rear spoiler that flows into the air filter housing and then into the turbochargers. The turbos compress the air to a maximum of 26.8 pounds per square inch (1.85 bar) – more than double the boost of the previous 911 Turbo. At about 2,500 rpm, wastegates on the turbochargers open to reduce boost to a maximum of 23.9 psi (1.65 bar). From the turbos, the intake air flows through dual intercoolers and then is merged upstream of the throttle butterfly. Porsche was the first carmaker to employ intercoolers for turbocharged cars. The intercooler reduces the temperature of the compressed charge, boosting power and enhancing component longevity.

The 2001 911 Turbo uses a dry-sump lubrication system like that on the Porsche GT1 and GT3. An external oil tank is attached directly to the engine, and the engine uses eight oil pumps – two in the crankcase (one pressure and one scavenging), a double scavenging pump on each cylinder head and one scavenging pump for each turbocharger. This setup keeps oil level in the tank at maximum even under extreme acceleration, braking, and cornering. A cyclone-shaped oil defoamer in the tank ensures a consistent oil supply for lubrication and operation of the VarioCam® Plus valve lift and timing system. (The 911 Carrera and 911 Carrera 4 use an integral dry-sump lubrication system.)

The 911 Turbo lubrication system holds 11.6 quarts (11 liters) of oil. Porsche replaced the dipstick with an electronic oil level monitor that ties in with the standard onboard computer. The driver can check the oil level on the computer display when the car is running at idle speed at normal operating temperature and resting on an even surface.

The 911 Turbo engine uses double overhead camshafts (DOHC) and four valves per cylinder, compared to the single overhead cam (SOHC) two-valve layout of the previous 911 Turbo. The 2001 911 Turbo introduces a new version of the Porsche VarioCam valve timing system. Called VarioCam Plus, the new system provides adjustable valve timing plus two camshaft profiles and two sets of tappets to vary valve lift and duration.

In normally aspirated Porsche engines, the VarioCam system alters valve timing by using camshaft chain tension to switch the intake camshaft between two positions. The VarioCam Plus system in the 2001 911 Turbo is much different and is really two systems in one. With VarioCam Plus, axial camshaft adjusters move over helical ramps to offer continuous valve timing adjustment.

The “plus” part of VarioCam Plus affects valve lift and duration according to engine load and speed and gear selection. Each intake camshaft includes two sets of lobes to provide two camshaft profiles – a 3-mm low-lift, short-duration p rofile, and a 10-mm high-lift, long-duration profile. The high-lift “lobe” is actually a pair of lobes, one on each side of the low-lift lobe.

Likewise, there are two sets of hydraulic tappets – but in this case, it’s a “tappet-within-a tappet.” Each tappet cup includes two concentric cups joined by a bolt. At idle and low engine speeds and loads, VarioCam Plus positions the camshaft over the central lifter and with oil pressure raises the center tappet above the outer cup. The low-lift cam profile thus operates the zero-lash center tappet and the outer tappet waits in a stand-by mode. The low-lift, short-duration profile ensures higher velocity of the intake charge and minimizes exhaust gas left over from the previous combustion cycle (low overlap). The 3-mm lift mode reduces fuel consumption and emissions at low speeds.

At higher engine loads, where larger overlap would recirculate exhaust gas and boost torque, VarioCam Plus lowers the center tappet and positions the camshafts so that the two high-lift lobes contact the outer tappet. Dual valve springs ensure reliable, high-performance operation. VarioCam Plus also provides better cold starting.

VarioCam Plus accounts for much of the fuel consumption improvement in the 2001 911 Turbo. That improvement allowed Porsche to reduce the fuel tank capacity from 18.8 gallons to 16.9 gallons and still maintain the same cruising range as the previous model.

In addition, VarioCam Plus helps reduce emissions, enabling the 2001 911 Turbo to meet the Euro Level 3 and U.S. LEV standards.

VarioCam Plus requires precision measuring of engine speed, gas pedal position, engine oil and coolant temperatures, and gear selection. The ME 7.8 engine control module meets these requirements. The driver “requests” a certain level of power by gas pedal pressure. The ME 7.8 unit compares this request to its control maps and decides within milliseconds whether VarioCam Plus must cut in. While VarioCam Plus effects a major difference in engine behavior, the driver will only feel a steady building of power, not an abrupt switch.

Sequential multi-port fuel injection features separate fuel mixture control for each cylinder bank, and a coil-on-plug (“distributorless”) ignition system provides quick response and reliable operation. The ME 7.8 engine control module incorporates the E-Gas electronic throttle (“drive by wire”). Instead of the gas pedal pulling a cable attached to the throttle valve, it pulls a short cable connected to a pedal value transmitter in the dashboard. The transmitter uses a potentiometer to convert the pedal travel path and speed into an electronic signal. The control module processes the signal, sending it to an electric motor that operates the throttle valve.

By providing full computer control over air intake at all engine speeds, the electronic throttle control enhances throttle response and helps reduce emissions. The system also reduces parts, since it eliminates the throttle linkage and separate idle speed control.

The exhaust system also contributes to the lower emissions of the 2001 911 Turbo. The short exhaust manifolds use two-layer air-gap construction with minimal pipe length to the turbochargers. The short exhaust route minimizes energy loss before entering the turbos, ensuring minimal turbo “lag” for quick response.

There are four catalytic converters – two per side. A pair of small-volume catalysts positioned close to the engine and immediately downstream of the turbos “light off” quickly to reduce cold start emissions. The main catalysts ensure low emissions once the engine has reached normal operating temperature.

The standard six-speed manual transmission in the 2001 911 Turbo shares only a shift lever with the six-speed in the 911 Carrera 4. The 911 Turbo required a new transmission to handle the 60 percent increase in torque over the 911 Carrera 4 (415 lb.-ft. [560 Nm] in the 911 Turbo vs. 258 lb.-ft. [350 Nm] in the 911 Carrera 4).

The transmission uses a new case, reinforced shift cables, and new gearbox mounts. Inside, instead of shrinking the gears onto the shafts, the pinions run on a ring of support teeth (splines). As in a racecar, this design makes the gears easily interchangeable.

The 1st and 6th gear ratios are the same as in the previous 911 Turbo, but 2nd through 5th have been lowered slightly to take advantage of the new engine’s superior low- and mid-range torque. Like other Porsche manual transmissions, the 911 Turbo six-speed uses a dual-mass flywheel to minimize vibration, especially at low speeds.

For the first time in its 25-year history, the Porsche 911 Turbo offers an optional automatic transmission. The Tiptronic S five-speed automatic transmission system used in the 911 Turbo is also new, with stronger internal components and a major change in the Tiptronic shift logic. The floorshift selector and steering wheel shift buttons are the same as in other Tiptronic-equipped Porsche models.

The Tiptronic S floor shifter includes positions for P (Park), R (Reverse), N (Neutral), D (Drive) and, to the left of D, M (Manual). When shifted into D, the transmission offers full automatic operation of the five gears, yet with greater intelligence and sophistication than traditional automatic transmissions. For example, Tiptronic S downshifts when the driver brakes into a corner. In manual mode, the driver can shift with the Formula 1 racecar-inspired steering wheel controls.

The 911 Turbo introduces a new automatic mode shift control to the Tiptronic S transmission. Instead of using five shift maps (as in the 2000 Porsche models), the new version chooses from an infinite number of shift points to adapt to the driving conditions – and the driver.

The transmission responds to leisurely driving with low shift points for relaxed, quiet cruising. Rapid accelerator pedal movement and frequent changes in acceleration – as one might experience on a twisty stretch of road – trigger a change to higher shift points and a strategy that holds lower gears longer. The Tiptronic S will immediately adjust the shift point strategy to the current driving style. A continuously engaging torque converter lock-up clutch works in all gears except 1st to optimize efficiency. To ensure smooth shifting, the Motronic engine control unit slightly reduces engine torque during gearchanges by re t a rd i n g ignition timing for a fraction of a second. The lock-up clutch also ensures quick shift response when using the manual mode. When coasting in overrun, the lock-up clutch minimizes load change responses.

The Tiptronic S transmission even behaves like a manual transmission when cornering. As the driver quickly releases the gas pedal while entering a corner, Tiptronic S holds the current gear. If the driver then applies the brake, Tiptronic S downshifts to provide engine braking going into the turn and acceleration when exiting. The Tiptronic S control module recognizes cornering by comparing speeds of the inner and outer wheels.

Sliding the shift lever into M from D at any time gives the driver instant manual c o n t rol of the Tiptronic S transmission. The car will hold the current gear until the driver upshifts or downshifts using thumb switches on the right or left steering wheel spokes. Pushing the “+” button upshifts, and pushing the button marked “–” downshifts. Tiptronic S also allows the driver to shift manually with the steering wheel switches even when the shift lever is in “D”. Manual shifts occur quickly, with no loss of tractive force. That is, shifting up or down does not reduce engine speed, as it does when taking your foot off the gas when shifting a manual transmission.

A short-term manual mode allows the driver to shift with the buttons even when the gear selector is in “D.” This mode allows the driver to quickly downshift manually to overtake, for example. The transmission will switch back to automatic mode unless the driver makes another manual shift within eight seconds.

The Porsche Tiptronic S automatic transmission offers far more control than the manual shifting option of so-called “manumatic” transmissions in other cars. Performance benefits include:

Porsche pioneered the all-wheel drive supercar with the limited production 959 of the mid-1980s. Although not imported to North America, the turbocharged 959 became a Porsche legend and paved the way for the first standard - production all-wheel drive Porsche 911 Turbo, which arrived for 1996.

As in the previous-generation 911 Turbo, the 2001 model uses an all-wheel drive system based on a viscous multi-plate clutch. The previous system located the viscous unit in the rear transaxle. In the new-generation 911 Turbo, Porsche installed the viscous unit directly behind the front diff e rential, simplifying assembly and maintenance and moving some weight to the front.

The all-wheel drive system directs five-to-40 percent of the torque to the front wheels, depending on available traction and power applied. The viscous unit compensates for differing wheel speeds during cornering. While the 911 Turbo exhibits superior traction on all road surfaces, Porsche did not intend the all-wheel drive system as an all-weather traction assistant.

Because Porsche increased the bending and torsional stiffness of this platform, the new-generation 911 Turbo eliminates the structural tube that enclosed the driveshaft on the previous car. The all-wheel drive system adds just 120 pounds (54 kg) to the car.

The standard Porsche Stability Management system (PSM) gives the 911 Turbo the highest level of stability in racetrack performance driving and adds another measure of dynamic safety on slippery roads. The PSM system also provides traction control to the rear wheels.

PSM can detect any loss of grip at the front or rear wheels and prevent instability by applying selective braking (braking one wheel) to keep the car on course. On slippery roads, PSM can help keep the 911 Turbo going in the direction the driver steers. On the racetrack, PSM can lend a “helping hand” through the slalom and fast turns.

PSM collects data from a steering angle sensor, lateral acceleration sensor and the ABS wheel speed sensors to determine if the car is heading in the direction the driver is steering. If PSM detects any deviation, it attempts correction by applying an opposite yawing moment – braking one inside or outside wheel to nudge the car back on course.

PSM requires an electronic throttle (“drive-by-wire”) because it may need to reduce power – not just apply selective braking – to help restore stability. PSM reduces power first by adjusting ignition timing and then, if necessary, fuel flow. The PSM system operates so quickly that most drivers likely will not feel it making corrections. The driver can disengage PSM with a dashboard switch. However, for safety, PSM will engage during braking and then disengage when the driver lifts off the brake.

A warning lamp on the instrument panel indicates PSM operation. While confident in the system’s ability as a dynamic handling aid, Porsche cautions drivers that PSM cannot counteract the laws of physics, such as gravity and available friction. The driver should heed the light and adjust his/her driving technique. In non-technical terms: SLOW DOWN!

Porsche Press kit 2000

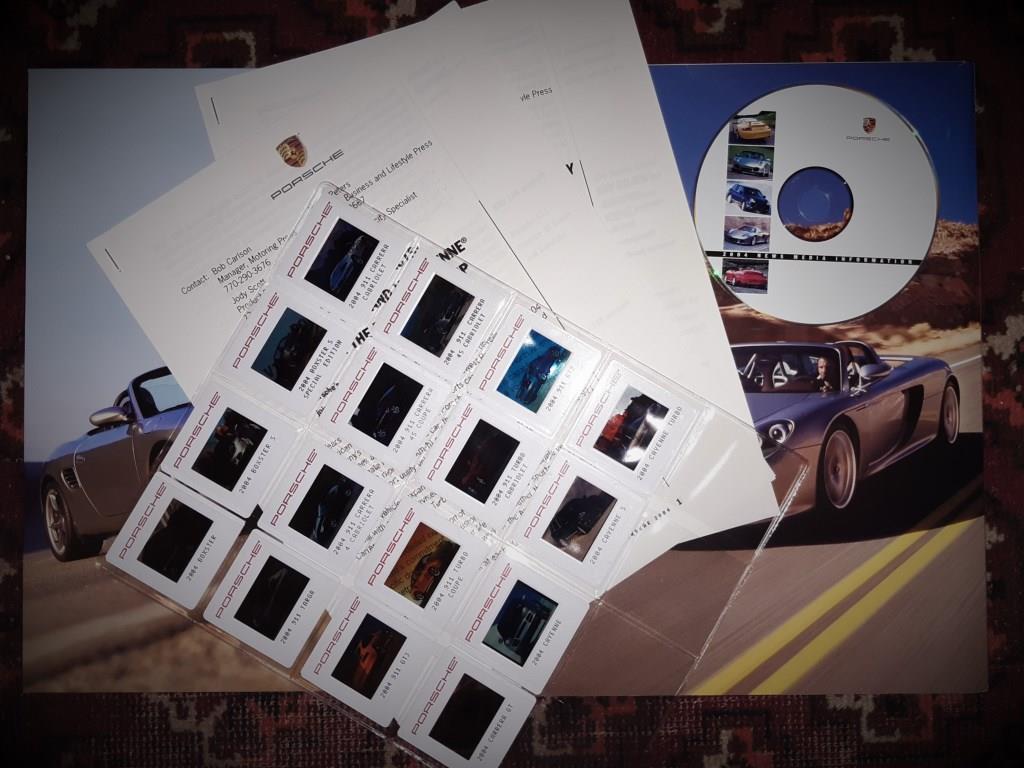

Porsche Press kit 2004 - USA

Porsche Press kit

Porsche Literature

Our Porsche Cars